Virtual trade show

|

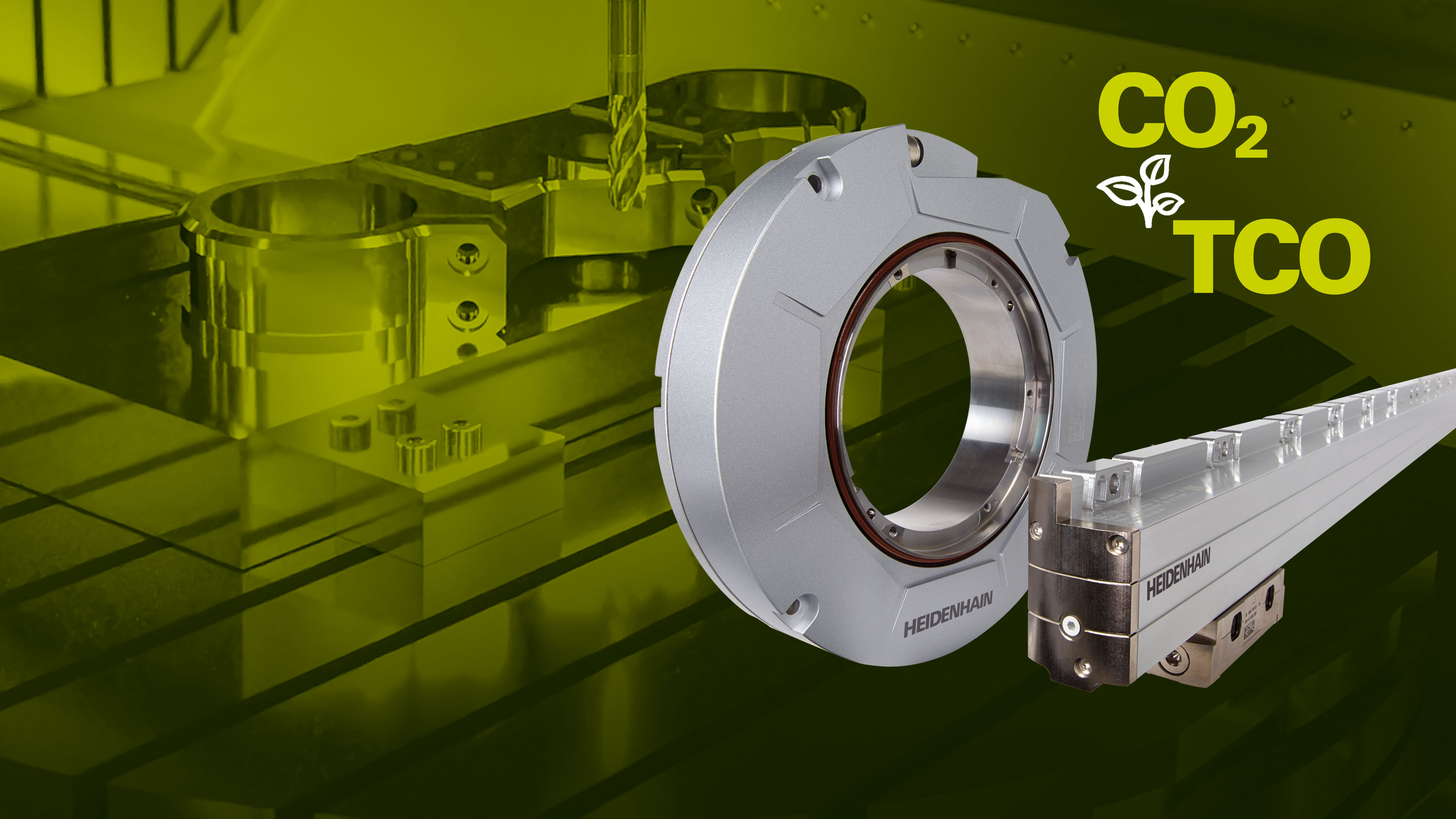

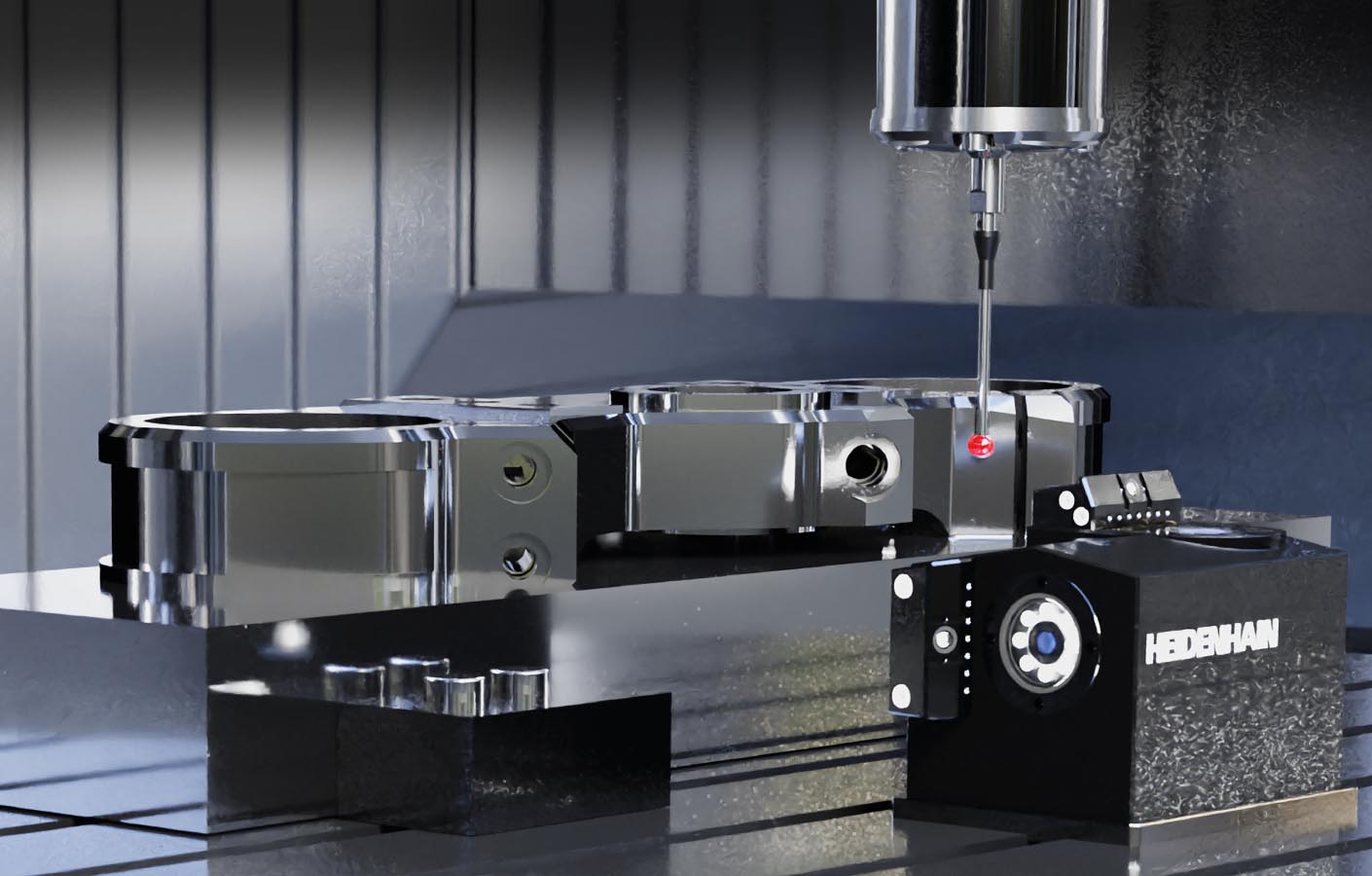

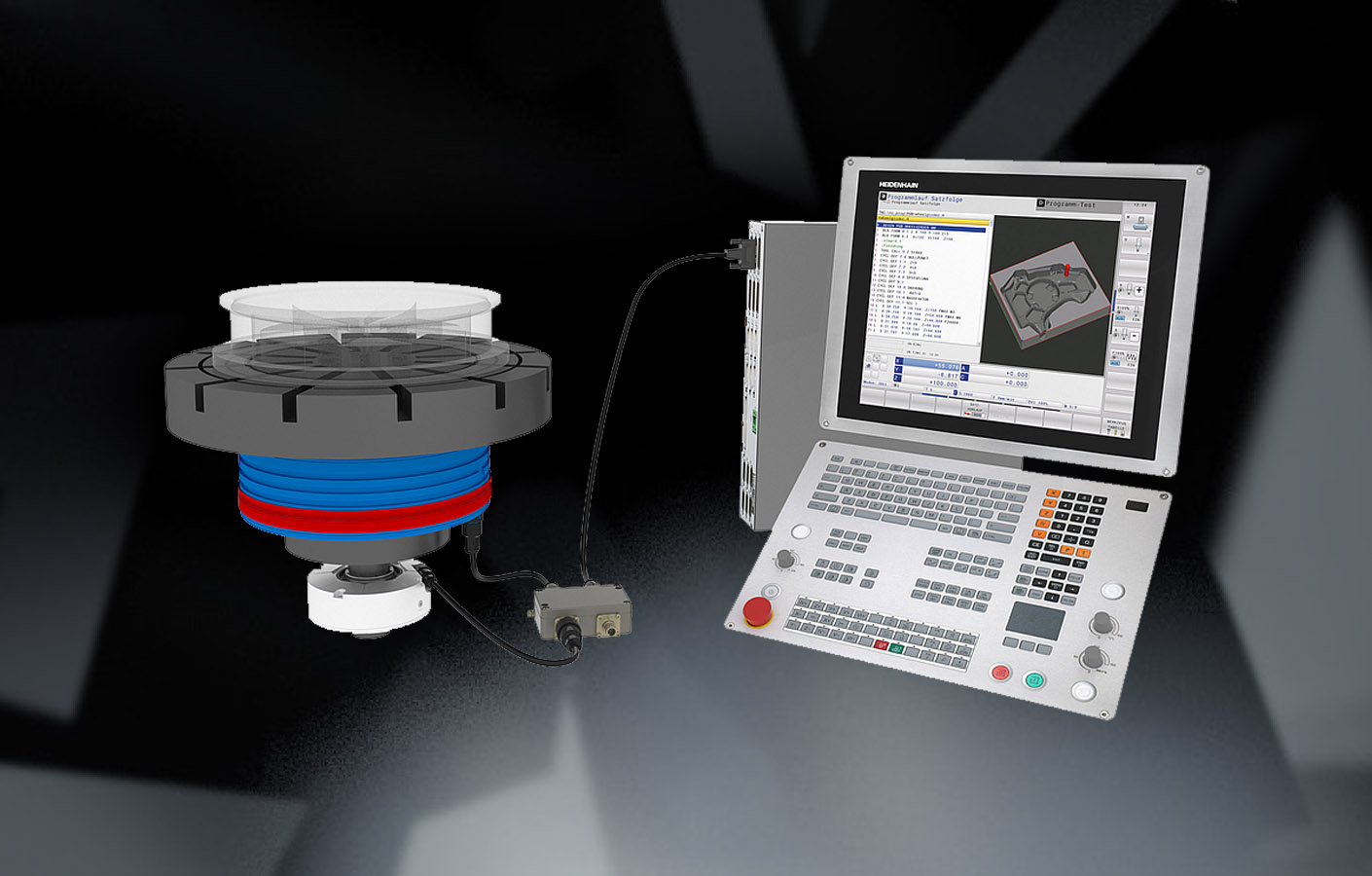

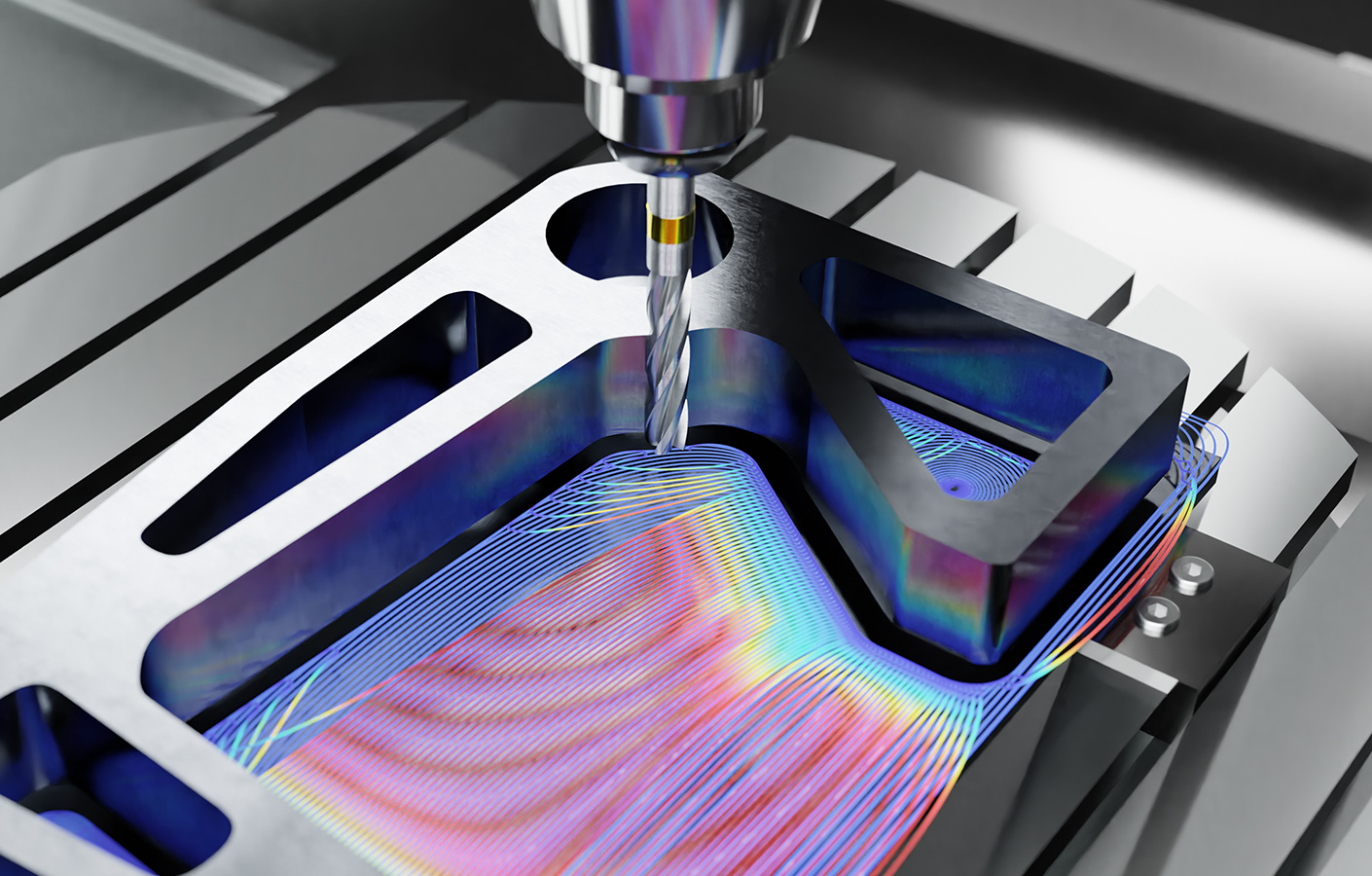

Machine tool

Discover the EMO highlights from HEIDENHAIN online!

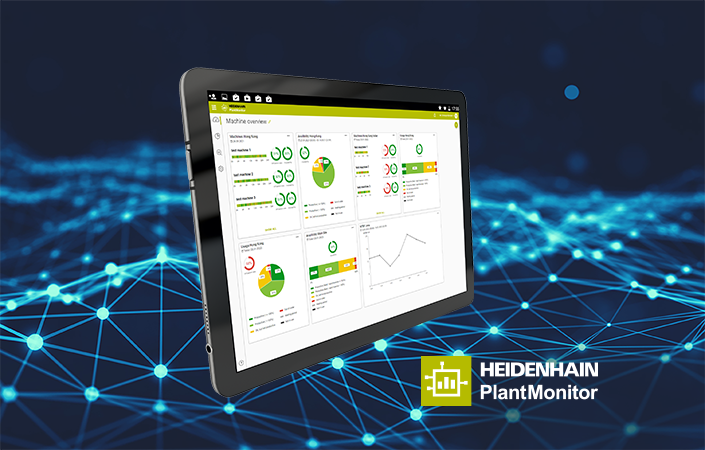

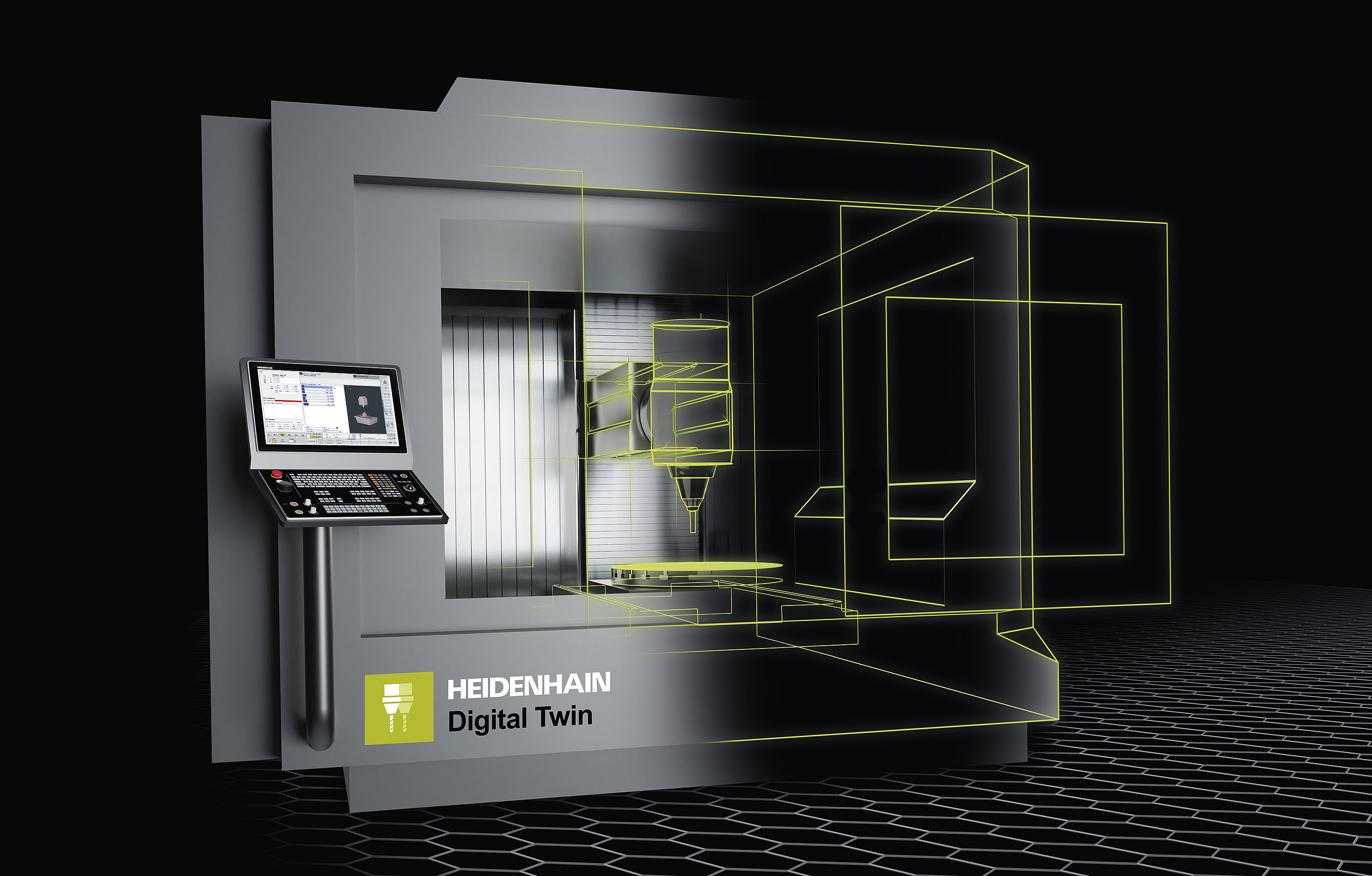

- Find the newest videos about the StateMonitor software and the TNC7, the new level of CNC control

- The new MSY motors and the new generation of METRO and SPECTO length gauges

- Solutions for greater process reliability and a smaller carbon footprint of your production floor